In 2024, the industrial added value of petrochemical enterprises above the designated size in Fujian Province grew by 7.5% year-on-year. Our province has 1,114 petrochemical enterprises above the designated size, generating a total revenue of RMB 538.04 billion. Fujian has now emerged as a major petrochemical hub in China. It boasts an annual production capacity of 45 million tons of oil refining, 5.9 million tons of ethylene, 5.4 million tons of paraxylene (PX), and 7 million tons of purified terephthalic acid (PTA). It leads the world in caprolactam production capacity, while its output of nylon and lithium hexafluorophosphate ranks among the highest globally and domestically. And it holds the fourth-largest ethylene production capacity in China.

Development Orientation

Advancing integrated and refined development, Fujian will focus on setting up two bases and one special zone (the Gulei Petrochemical Base, Meizhou Bay Petrochemical Base, and Jiangyin New Chemical Materials Special Zone). It will increase refining capacity, enhance the supplies of olefins, aromatic hydrocarbons and other raw materials, promote deep processing of petrochemical products, and develop plastics, rubber, and specialty chemicals. By 2025, the volume of the province’s petrochemical industry will reach RMB 1 trillion.

-

Basic Chemical Raw Materials

-

Deep-processed Petrochemical Products

-

Plastics and Rubber

-

Specialty Chemicals

Key Investment Areas

- Basic Chemical Raw Material Manufacturing

- Synthetic Materials Manufacturing

- Fine Chemical Industry

- Plastic Products Industry

- Chemical Fiber Manufacturing

Leverage Fujian’s coastal location to secure overseas light hydrocarbon resources. Develop ethylene production from imported light hydrocarbon cracking and propylene production from propane dehydrogenation. Promote diversification of raw materials and expand existing sources of olefin raw materials.

Leverage the province’s unique strengths in machinery, electronics, chemical fiber, and plastic processing industries. Accelerate the development of high-performance polyolefins, high-performance fluorine materials, special engineering plastics, specialty synthetic rubber, high-performance fibers, and functional film materials.

Prioritize projects based on electronic-grade special gases, wet chemicals, lithium battery additives, and other high-value-added fine chemicals.

Expand into high-end automotive plastics, packaging materials, agricultural pipes, and medical materials. Strengthen the design and production of plastic machinery and molds. Increase recycling efforts and waste plastic processing while developing biodegradable plastics.

Focus on developing foundational fibers, key strategic fibers, and cutting-edge fiber preparation and application technologies. Accelerate the development of advanced functional, highly-simulation, and bio-based foundational fibers; key strategic fibers such as high-performance T1000 and M55 carbon fibers and para-aramid fibers; as well as cutting-edge fibers including nanofibers, smart fibers, and fibers for biomedical use. Increase the proportion of differentiated, functional, and high-value-added products.

Investment Carrier

Investment Projects

-

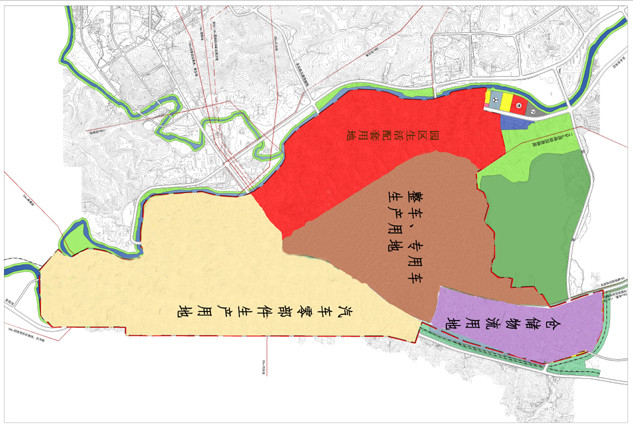

Petrochemistry Project, Chemical New Materials Area of Fuzhou Jiangyin Port City Economic Zone

Cooperation Mode:Collaborate

Project Funds:discussed in detai -

Petrochemistry Project, Gulei Petrochemical Base

Cooperation Mode:Collaborate

Project Funds:discussed in detai -

Petrochemistry Project, Chemical Project of Quangang Petrochemical Industrial Park

Cooperation Mode:Collaborate

Project Funds:discussed in detai

-

Electronic Information and Digital

-

Featured Modern Agriculture and Food Processing

-

New Materials

-

Biology and New Medicine

-

Advanced Equipment Manufacturing

-

Metallurgical

-

New Energy

-

Building Materials

-

Petrochemical

-

Modern Textiles and Garments

-

Modern Services

-

Artificial Intelligence (AI)

-

Hydrogen Energy and Fuel Cells

-

New Energy Storage

-

Low-Altitude Economy